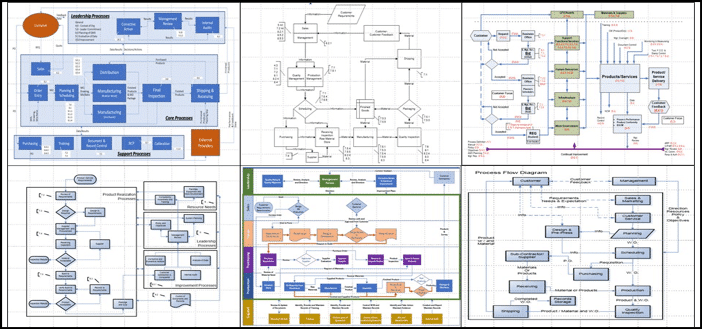

That’s right…one size fits one QMS. It’s how it has always been intended yet MOST folks see it as a one size fits all QMS. Let’s face it…your organization is unique. Sure, we all have customers, processes, people, resources, ISO lead auditor training, etc. but no one, and I mean no one, has your unique business characteristics. The above maps illustrate many ways an organization can understand its processes.

Yes, you may produce products others could produce, however, do they have the same product knowledge, equipment, tools, personnel, business culture, resources, organizational structure, physical location, etc? Do they have the same quantity of people and equipment or the same physical foot print in the same facilities? Do they work one, two, three, or four shifts? See…each of these business attributes has an impact on how your QMS lead auditor training behaves and functions. Sound rational?

Don’t be fooled with a one size fits one approach. There are many supplier organizations that want to sell you a “package”, a virtual plug and play tool, to help you pass QMS audits…is that what you REALLY want? Do you believe that is what your customers want? Or do you want to be a strength in the supply chain that can be depended upon by customers to always deliver quality products, on time at or below costs? In our competitive work environment, you need to become a more effective supplier not just another organization that is “just passing” audits. Those types of short-term intellects will be consumed by you in the future!

One of the most important tools to use in this one-size-fits-one approach is how you map your processes. Do you academically understand what physically is happening in your organization? In some companies, leaders only know what is told to them or what data is presented yet the cause of the data results, is an output of your processes. You need to understand what your processes are, how they interact, and if they are under control, sometimes with an ISO lead auditor training. Sound reasonable?

Why process mapping? Mapping of processes has been used for many years as a way for workers to “see” what they are doing to themselves. Mapping becomes a tool for organizational stakeholders to identify bottlenecks, understand where process or product problems come from and enable them to more clearly see how their business functions so they can stabilize when needed and improve when motivated. These same processes, once better understood, allow a company to exploit its capabilities as a market advantage and reduce or eliminate its risks. Sounds logical?

Your processes are YOUR PROCESSES. Whomever you find to help you become a supplier of choice, make sure they have your best interests in mind and work to understand YOUR BUSINESS not force you into their limited paradigm of understanding.

Lead Auditor Training

One way to achieve a one-size-fits-one quality management system is through lead auditor training. This involves educating and training individuals within the organization to become lead auditors, who are responsible for overseeing the implementation and maintenance of the QMS.

Lead auditor training not only allows for a more thorough understanding of processes within the organization, but also provides individuals with the skills and knowledge to conduct audits and identify areas of improvement. This type of training helps to ensure that the QMS is tailored specifically to the organization’s needs and business characteristics.

Additionally, ISO lead auditor training can help organizations stay up-to-date with industry standards and regulations, ensuring compliance and continuous improvement. This ultimately leads to a more effective QMS and a competitive advantage in the market.