APEX has developed a simple but effective way to implement, mature, and use a QMS ISO 9001 internal auditor training that is supplier specific and focused on customers. Maps, Methods, and Measures.

“If everybody is thinking alike, then somebody isn’t thinking” General George S. Patton, Jr. (1885-1945).

Think about this…all work is accomplished through processes. Period. Not all processes have associated documented procedures. Wait…what? That’s right, all work is accomplished through processes which are the transformation of inputs into outputs. Simple, yes? Well…conceptually most people get it yet when it comes to understanding processes AT A LEVEL NEEDED BY THE ORGANIZATION…people struggle. Why? Because an ISO 9001 training process can be as simple as completing a form or as complex as designing and assembling a 5th generation fighter aircraft like the F-35.

Maps are YOUR PROCESSES described in a way that makes sense to YOU. This is the one size fits one QMS approach of APEX. Each organization, interested in improving its capability or seeking to provide transparency to how it works, must first academically understand what practically is happening in its organization. Creating maps provides clarity to organizations by causing people to work together, uniting team members assisting them in overcoming personal biases, and seeking solutions that work best for all interested parties. Mapping allows an organization to see the future by developing a plan of what could be. By mapping your processes, everyone involved becomes more aware! This awareness allows for organizational change…before you can improve an ISO 9001 lead auditor training process, you have to think about it differently! Mapping is a key tool to help you “get there”.

When it comes to YOUR PROCESSES listen to what the QMS standard writers have said:

The structure of clauses (of a QMS) is intended to provide a coherent presentation of requirements, rather than a model for documenting an organization’s policies, objectives and processes.

The structure and content of documented information related to a quality management system can often be more relevant to its users if it relates to both the processes operated by the organization and information maintained for other purposes. (Annex A, A.1 Structure and Terminology, ISO 9001:205 pg. 21)

So, what are YOUR PROCESSES? At what level do you need to map or develop flow charts or process maps? A formal QMS ISO 9001 course invites organizations to consider value processes such as managing customer relationships, reviewing and agreeing to provide products to needed requirements, selecting and managing suppliers, and having plans and processes to design products or services, when that is part of what the organization does, and controls to produce products or services that meet customer expectations. These might be considered core or key processes. These types of processes of the business generate value for their customers and stakeholders. Other processes like leadership, measuring and evaluating, and supporting processes such as how information is controlled and distributed are all vital to an organization’s effectiveness.

One more thing, consider the inputs and outputs of each process. Many organizations try showing inputs/outputs with a line drawn between two boxes…WHAT??? A line might show relationships or direction of flow but they certainly DO NOT define “inputs required and outputs expected for these processes” (ISO9001:2015, clause 4.4.1.a. pg. 2)

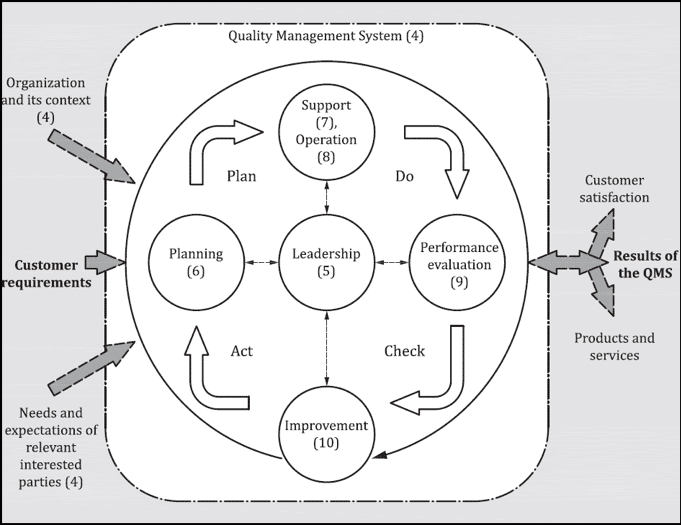

Standards writers have placed two diagrams in ISO 9001 and industry standards to help facilitate understanding, but again, THESE ARE NOT HOW YOUR BUSINESS FUNCTIONS!

(from ISO9001:2015 pg. viii)

This “model” above shows how the QMS ISO 9001 internal auditor training requirements SHOULD be working together to produce desired outputs and how an organization CAN USE THEIR SYSTEM TO IMPROVE through feedback loops. However, the above model IS NOT YOUR BUSINESS PROCESSES!

This model (Figure 1) is intended to be generic and allows users to try and see or understand the different elements of a process. Again, the above, Figure 1, IS NOT YOUR PROCESSES but a schematic to show interactions of elements of a process.

APEX helps organizations “get there” by working with process owners and stakeholders, walking the processes, challenging the current practice and implemented norm, helping them to “see” inputs and outputs, at a level they need to understand, and collaboratively identify what monitoring and measuring is needed to improve organizational effectiveness. Together, your team, who are your process experts, and APEX, who are experts in QMS interpretation and implementation, can determine, define and appropriately map the processes of your QMS that will not only assist in a more effective QMS which will increase your customer satisfaction but also a system that you can be used to improve. Your QMS ISO 9001 course is now set for other transformational efforts and can be used to sustain other business objectives. How can it do that? Because IT IS YOUR BUSINESS!

So…what do you want? A forced QMS that is pushed upon your business based on some off the shelf documentation model that forces you to over document processes? A restrictive QMS ISO 9001 lead auditor training that increases costs and adds no value to your organization or your customers? Or a customized, one size fits one QMS that enables your business, and supports the competencies of your people while ensuring you provide the highest quality of products on time at or below costs? It’s all about YOUR PROCESSES!